Please note that the following information will soon be available in English. Until then, we invite you to download this machine’s datasheet.

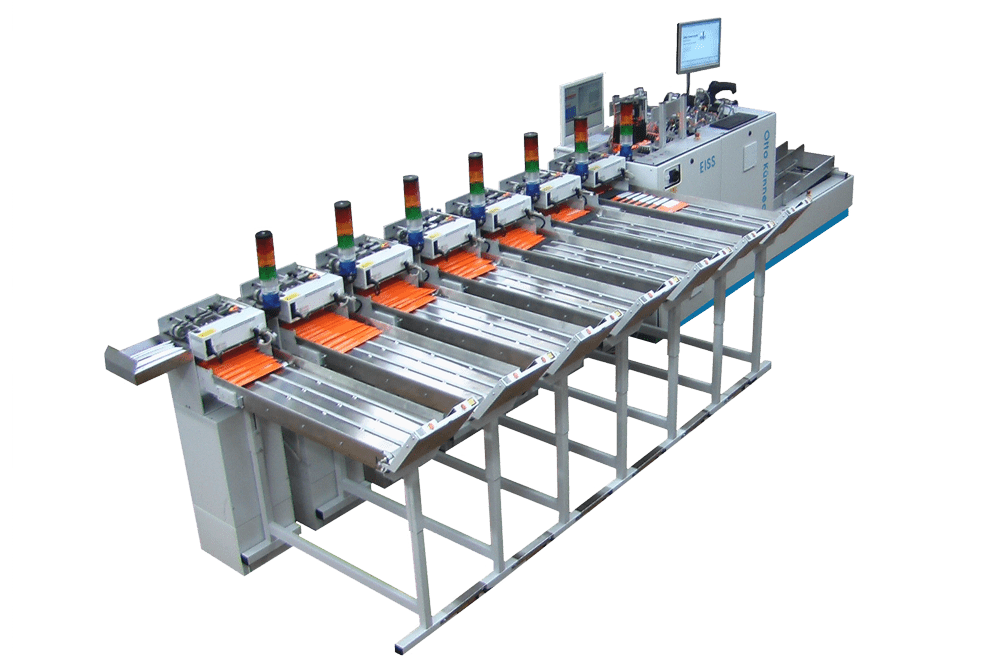

Quality control

Umschläge werden identifiziert und mit der Datenbank abgeglichen. Faktoren wie Gewicht, bestimmte optische Merkmale wie Bar- oder QR-Codes werden gelesen und auf Richtigkeit geprüft. Fehlerhafte Sendungen werden ausgesteuert.

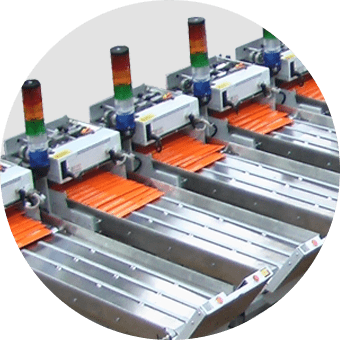

Final processing

Before the sorting on deposit belts or directly in postal boxing systems, additional optical markings can be applied with ink jet printing on the envelopes, or with labels with special mailing instructions. The sorted groups on the conveyor belts can be made more visible by using dividing stripes, batch kickers, or coloured markings.

- Optical recognition of most different features (bar code, QR code, logos, etc.)

- Modular construction and many extension possibilities

- Storing on conveyor belts or automatically in postal boxes

- Automatic labelling of the postal boxes possible

- Fully automatic sorting and checking of the envelopes

| Throughput | up to 8.000 envelopes / hour (depending on the application) |

| Operators needed | 1 |

| Power supply | 3ϕ, 400v 50/60Hz |

| Footprint | Flexibel |

| Temperaturs/Humidity | Optimal: 20-25°C room temperature, 60 % relative humidity |

“Never before has reliable sorting and inspection of envelopes been this easy: the EISS executes all steps of the workflow automatically to guarantee an optimal result.”

Diemtar Wegner, Production Manager

Do you have any questions? We are happy to talk to you at any time. Write us a message or just call us. We look forward to your inquiry!

Otto Künnecke GmbH

Bülte 1

37603 Holzminden

Germany

Sales-Team

Fon +49-5531-9300-888

sales@kuennecke.com