Cards

Cards are still the simplest and most secure method of identification, access authorization and participation in marketing or loyalty programmes Our solutions supply all options here for individual processing activities.

In our process chain the cards are continuously traceable and thus can be surely identified everywhere. Quality and integrity can be simultaneously controlled. The modular construction concept of our machines offers the entire bandwidth at combinations and is at any time flexibly extendable.

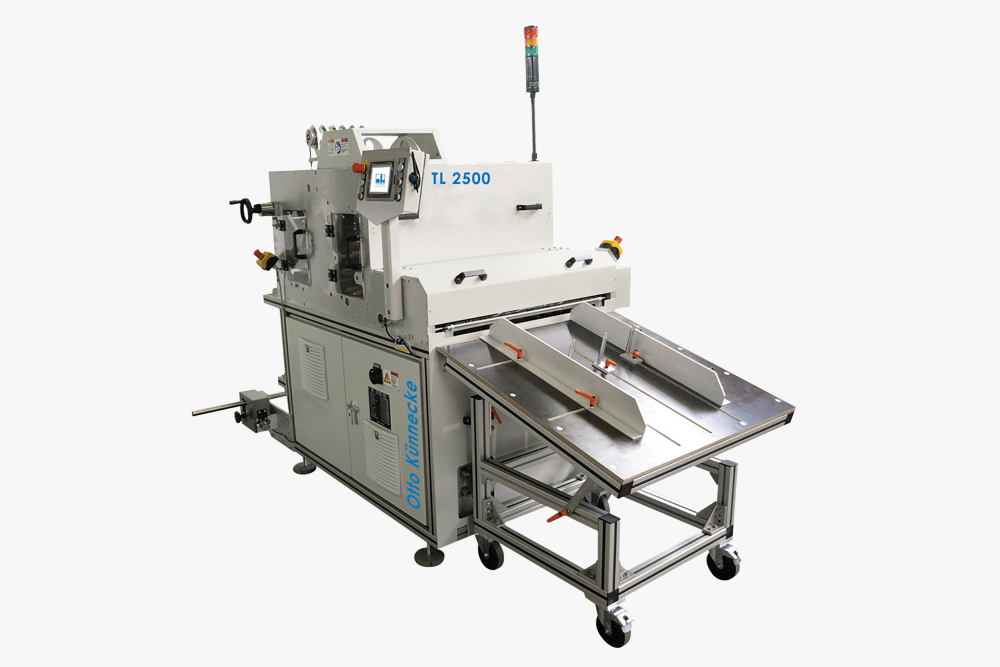

The overlay and core films which are needed for the card production are cut to the wanted processing size. Thus unit sizes such as half pages or strips can be produced; or precise edge trimming can be carried out.

Our solutions

We offer manual and semi-automatic systems for the collating of core and overlay films for the card production. Core and overlay films are collected, stacked precisely upon each other, and welded together. According to whatever system, various quality controls can be included here in order to notice and report for example missing films or to examine the correct position of the sheets before the welding.

Our solutions

According to the size and the complexity of the requirements of your card production, we offer for the punching of laminated sheet sets various stamping systems with different specifications and features such as automatic feeding, and a cutting or perforation module. So you can remain flexible and arrange your card production for maximum efficiency.

Our solutions

Verification & quality control

We identify and examine products according to identity, presence, situation, tolerance and quality. For this purpose we use different identification systems such as video cameras, magnetic strip readers and chip reading facilities or bar code readers. Also physical features like weight or form can be examined. With the systems we use, products with centrally stored identification numbers and specifications or information contained in databases can be compared with the recorded data and their correctness checked.

Further features which we check include bar code, chip, magnetic strip, Multi ID Reading, OCR, RFID, labels and other quality features. Modules for the quality control can be integrated in various systems for the card production as well as in the further processing. Through a comprehensive quality control faulty productions can be avoided and the highest product security can be guarantee.

Our solutions

Personalizing & marking

Many different technologies are used in the case of the personalization of cards. From the marking of cards by way of dispensed labels, printed labels or holograms up to digital data transfer, we offer a wide range of all usual personalisation procedures.

This includes among other things lasers, thermotransfers, magnetic strips, chip codes (contact adhesive or RFID). Our modules for the personalisation can be integrated into almost all systems and allow thus also a flexible extension of the possible field of application.

Our solutions

Our modules for the sorting & grouping of cards can be integrated into almost all further processing solutions. Predetermined card set sequences can be set up, or groups formed, which are database supported. So in this way, for example, postage-cost-optimised dispatch groups may be created, or sorted cards may be directly fed to magazines which are then transported for suitable further processing, e.g. the personalisation. As an option, markers or separating cards or documents can conspicuously make the formed groups and sequences more visible.

Our solutions

Next to the classical intermediate storage modules such as retainer stars, roundtable storage or card buffers, other methods for the pre-storage, interim-storage, or the final storage of cards are available even as complete picking and storing systems. On the one hand this facilitates the efficiently synchronised processing of the cards and on the other hand brings with it many advantages for complex applications, in which for example many individual designs, pre-personalised or not personalised cards are to be processed in each case in small lot sizes.

A (intermediate) storage of the cards can make sense between different processing steps and according to your individual application. So can database-supported groups for example be created, which are so packed for the later dispatch that no unnecessary postal charges arise and that the packing units are used up optimally.

Our solutions

We offer a great number of packaging solutions that complement with our other modules for packaging and dispatch preparation. Cards can, for example, be fed onto carrier envelops, or be packed as a group with the banderole method.

Next to the enveloping in Film Bags or Express Mail Envelopes, packaging methods also include blister packs, shrinkage tunnel packaging or cardboard boxes. Thanks to database-supported processes, packaging can be used optimally in order to achieve reduced postal charges. Furthermore, enclosures can be selectively added to the packages, such as delivery notes, packing lists, invoices or other documents.

The automatic feeding of personalised or standardised dispatch labels is possible.

Our solutions

We process all usual card types and can also design our systems on request for cards in special formats.

Here you will find a selection of examples of the cards which are used with our solutions.

Types of cards which are manufactured and processed on our machines include:

| Materials | e.g. PVC, polycarbonate, paper, metal, wood |

| Standards | ISO/IEC 7810, ID-1, ID-2 |

| Additional elements | e.g. chip, magnetic strip, RFID, embossing, punching, perforating, etc. |

| Optical features | Bar code, QR-code, different fonts, illustrations and optical security features (e.g. UV ink, graphic objects, holograms, etc.) |