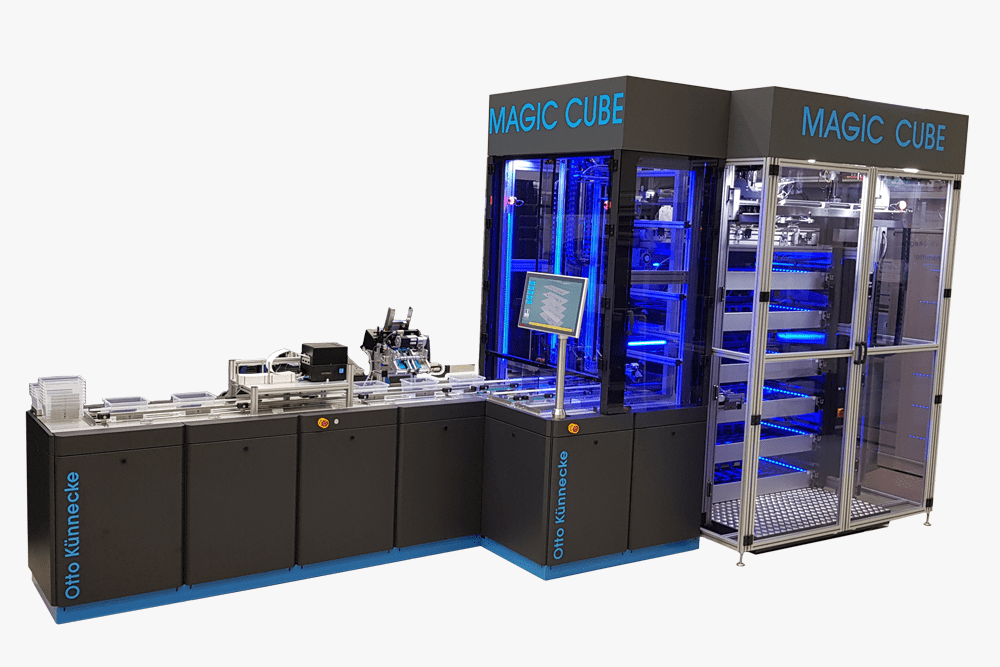

Sorting and storing machines

Card Sorting and Storage Machine Card Kiosk

grouping machine

Storing and sorting machines

Which challenges does a warehouse face if an enterprise plans an efficient operating process and does not want to accept any losses through deficiencies or overstocking? The answer to that is in a kitchen, more precisely said, in a refrigerator. The kitchen is the factory, the refrigerator the warehouse. Here the sensitive products lie, they need cooling, one more and the other less, and already it starts – products have specific requirements. And then it is a question of the retrievability. Where do I find what? He who has a system, clearly has an advantage.

Of course the warehousing requirements of a company are much more complex and demanding, than those of a kitchen. Vast quantities of different products in different quantities must be permanently in store in order to maintain an uninterrupted production. However, the products are not supposed to be hoarded in enormous quantities. That only ties up valuable capital that is better invested in other places. The principle must be: Guarantee availability, but avoid wastage.

Intelligent warehouse management begins with a needs analysis of what an enterprise needs in order to be permanently sure of its ability to produce. The size of a warehouse is derived from that. Products have certain requirements, such as regulated temperature and humidity, and if they are sensitive and need special care in their handling. Are the products or parts large or small, easy or heavy or dependant on certain security or safety requirements? The list of factors could be continued almost endlessly and is industry specific.

Regardless of which branch it is, an enterprise needs an intelligent warehouse with data-supported receipts and dispatches. Possible deficiencies must be recognized previously before they even occur. A database must know which one of the stored products has first to leave the warehouse, in order not to be overlapped. An overview of the stock levels must occur at the press of a button. Laborious stock takings and bad surprises must become things of the past. A press of a button must suffice in order to know how much capital is bound up in the warehouse or how much is needed in order to fill it. That is the financial part of the warehouse. Additionally, there comes the daily administration of the collating, the equipping, the gathering of the daily orders and the whole paperwork regarding each of these orders.

These processes must run 100 percent without error. No mistakes anymore, no returned parts, no production in error – this added value is cash profit and safeguards the quality of the products and the jobs in the manufacturing.

We have decided on an automation of these processes. Fully automatic or semi-automatic, whichever, configured according to the customer`s requirements and specified to the products. There are also restrictions. Those must be overcome. Or we may be unable to solve your problem – then we shall say that to you.